Tensile strength

|

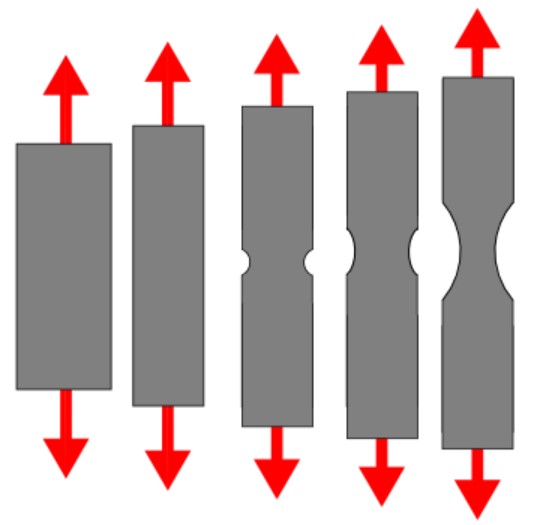

This schematic depiction illustrates how, prior to necking, the entire material evenly undergoes plastic deformation. Once an unstable neck forms, the cross-sectional area of the neck will continue to decrease under load, while the un-necked material no longer plastically deforms. |

Contents |

[edit] Introduction

Tensile strength can be defined as the force required to pull a material in opposite directions to the point of permanent deformation or failure. Tensile strength is the resistance to tension. It is the opposite of compression strength, which is the resistance of compression when items are pushed together.

As an engineering characteristic, tensile strength is significant in materials used for construction. It gauges the suitability of building materials for various applications, particularly those materials that will be required as structural elements. When describing the properties of materials such as metals and alloys, the tensile strength may be included in material specification documents.

[edit] Stress, tension and tensile strength

Tension is a state of stress in which a material is being pulled apart, for example a cable that is attached to a ceiling with a weight fixed to its lower end. Under the influence of gravity, the weight exerts a downward pressure that produces tension in the cable, as does the reaction at the fixing point in the ceiling.

Tension has different effects on materials: concrete does not accommodate tensile stresses well and may crack and suffer extensive damage – with little elongation; while steel is very strong in tension and can elongate substantially under load. It is for this reason that concrete is often reinforced with steel rebar.

The amount of tensile stress a material can tolerate before being pulled apart is defined as its tensile strength. When the stress of certain types of material reaches tensile strength, it will distort to form an area referred to as a neck. This constricted region is typically where the material will fracture. This occurrence is sometimes referred to as the necking phenomenon.

[edit] Three types of tensile strength

Engineering properties associated with materials can be measured according to three different types of tensile strength. These include:

- Yield strength. This refers to the approximate amount of stress a material can undergo prior to experiencing permanent deformation of 0.2% of its original shape.

- Ultimate strength. Ultimate tensile strength (UTS) is measured in units of force per cross-sectional area. It refers to the maximum stress a material can undergo prior to experiencing failure to the point it will be unable to return to its original shape. UTS is an intensive property - it is a characteristic of the material that will be consistent regardless of the sample size. (Note that tensile strength and ultimate tensile strength are not completely synonymous, although they are sometimes used interchangeably. UTS is a specific type of tensile strength.)

- Fracture or breaking strength. This type of tensile strength is the point (or stress value) during a tensile strength test where rupture to the material occurs.

This chart shows the ultimate tensile strength of some typical materials (depending on the manufacturing process and purity or composition of the materials).

| Material | Ultimate tensile strength (MPa) |

| Silicon | 7000 |

| Basalt fibre | 4840 |

| Boron | 3100 |

| Diamond | 2800 |

| Sapphire | 1900 |

| Tungsten | 1510 |

| Brass | 500 |

| Structural steel | 400 to 500 |

| Bamboo | 350 to 500 |

| Copper | 220 |

| Human hair | 200 to 250 |

| Wood (pine, taken parallel to the grain) | 40 |

| Rubber | 16 |

| Marble | 13 |

| Concrete | 2 to 5 |

[edit] Testing tensile strength

It is possible to measure the tensile strength of materials precisely by conducting an elongation test under carefully controlled conditions. This tensile test (also known as a tension test) uses a universal testing machine (UTM) to stretch the specimen at slow, continuous, standardised rate until it fails.

UTMs can typically have testing capacities of up to 53 Mega Newtons (MN) which is equal to a 5,404 tonne force.

[edit] Related articles on Designing Buildings

- Compression.

- Compressive strength.

- Structural stress.

- Tensegrity.

- Tensegrity bamboo pavilion

- Tensile structures.

- Tension.

- The development of structural membranes.

- Ties.

[edit] External resources

Featured articles and news

Scottish parents prioritise construction and apprenticeships

CIOB data released for Scottish Apprenticeship Week shows construction as top potential career path.

From a Green to a White Paper and the proposal of a General Safety Requirement for construction products.

Creativity, conservation and craft at Barley Studio. Book review.

The challenge as PFI agreements come to an end

How construction deals with inherited assets built under long-term contracts.

Skills plan for engineering and building services

Comprehensive industry report highlights persistent skills challenges across the sector.

Choosing the right design team for a D&B Contract

An architect explains the nature and needs of working within this common procurement route.

Statement from the Interim Chief Construction Advisor

Thouria Istephan; Architect and inquiry panel member outlines ongoing work, priorities and next steps.

The 2025 draft NPPF in brief with indicative responses

Local verses National and suitable verses sustainable: Consultation open for just over one week.

Increased vigilance on VAT Domestic Reverse Charge

HMRC bearing down with increasing force on construction consultant says.

Call for greater recognition of professional standards

Chartered bodies representing more than 1.5 million individuals have written to the UK Government.

Cutting carbon, cost and risk in estate management

Lessons from Cardiff Met’s “Halve the Half” initiative.

Inspiring the next generation to fulfil an electrified future

Technical Manager at ECA on the importance of engagement between industry and education.

Repairing historic stone and slate roofs

The need for a code of practice and technical advice note.

Environmental compliance; a checklist for 2026

Legislative changes, policy shifts, phased rollouts, and compliance updates to be aware of.